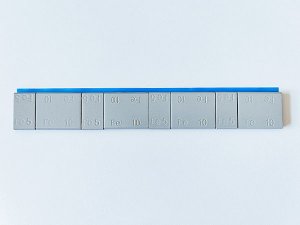

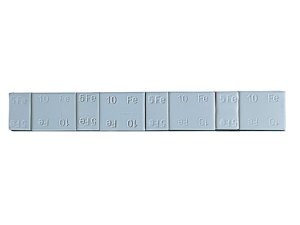

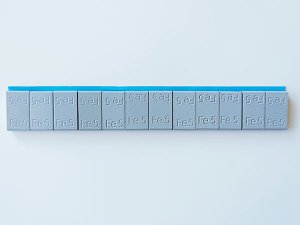

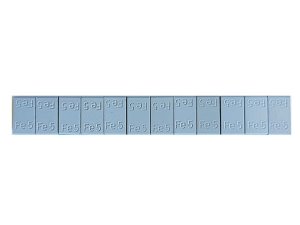

Comparison of vertical balance block and horizontal balance block.

What's the difference between a vertical balance block and a horizontal one? The following is a brief introduction to the car accessories:

Vertical balance weight loading and unloading of the wheel, though less horizontal balancing instrument is convenient, but its wheels quality direct pressure on the spindle center line, not only do not form a strong torque, and vertical sensor under static load is smaller than the wheel quality. The strain part is a square strain plate with a working table, and the horizontal sensor is designed to be one or both sides, which is much more stable than the mechanical structure of a single horizontal sensor of horizontal balance block. There are many empty slots on the square strain plate to reduce the rigidity of the strain plate, which greatly improves the sensitivity of the sensor system.

Horizontal balance weight is measured wheel loading and unloading is convenient, the advantages of the mechanical structure and sensing device is simple, cost is low, so our products are very popular to repair and maintenance, is also the ideal choice of the manufacturer. But because of the wheels on the cantilever long spindle form a lot of static torque, impact sensing system initialization state, especially the vertical sensor pre-tightening condition, after long time use precision is difficult to guarantee, zero drift is bigger also, relatively low sensitivity, but can entirely meet the requirements of the general operation of the vehicle. There is a fundamental difference between the old iron balance block, that is, the card and the balance block are riveted. Higher precision than welding, beautiful appearance. It is not easy to deform, and it can be reused, which greatly reduces maintenance costs and costs.

The vertical balance block has high precision and can generally reach 3g, with good repeatability and stability. Aluminum counterweight used (non-ferrous metal aluminum, zinc, iron) die casting machine high temperature die casting molding, a total of 4 kinds of two varieties of 60 kinds of specifications, product appearance using electrostatic spraying epoxy resin processing, has the advantages of anticorrosive, environmental protection, prevent deformation, is currently the car wheel balance of new products. Many higher than that of cast iron, beautiful and easy, can according to the customer the advantage of horizontal balance weight is measured wheel loading and unloading of convenient, mechanical structure and sensing device is simple, the cost is low, so our products are very popular to repair and maintenance, is also the ideal choice of the manufacturer. But because of the wheels on the cantilever long spindle form a lot of static torque, impact sensing system initialization state, especially the vertical sensor pre-tightening condition, after long time use precision is difficult to guarantee, zero drift is bigger also, relatively low sensitivity, but can entirely meet the requirements of the general operation of the vehicle. There is a fundamental difference between the old iron balance block, that is, the card and the balance block are riveted. Higher precision than welding, beautiful appearance. It is not easy to deform, and it can be reused, which greatly reduces maintenance costs and costs. We use a variety of colors of epoxy resin, electrostatic spraying, can be guaranteed to never rust. New varieties are required to be developed.

Product

We serve you wholeheartedly!

Copyright © 2018 - 2019 TONGYU All Right Reserved.